The WE Knife Co. High-Fin is a folding knife designed by WE Knife Co. in collaboration with blade smith Michael Gavak. It excels in its looks and functionality as an EDC tool.

WE KNIFE High Fin Thumb Stud Knife

WE High-Fin is a highly functional, highly snazzy, rugged and classy folding knife featuring thumb studs and a frame lock mechanism. It is a 7” pocket knife with a 3” reverse tanto CPM 20CV hollow grind blade with a 4” blue titanium handle with caged ceramic ball bearings.

It is lightweight and weighs just 3.49 ounces configured for right hand tip-up carry pocket clip.

WE Knife High Fin Prices |

||

|---|---|---|

|

|

Check Price at Blade HQ |

|

Check Price at Chicago Knife Works | |

Key Specifications of WE Knife High-Fin Series

First Impressions of WE Knife High-Fin

The WE Knife High-Fin came in a regular WE knife branded box.

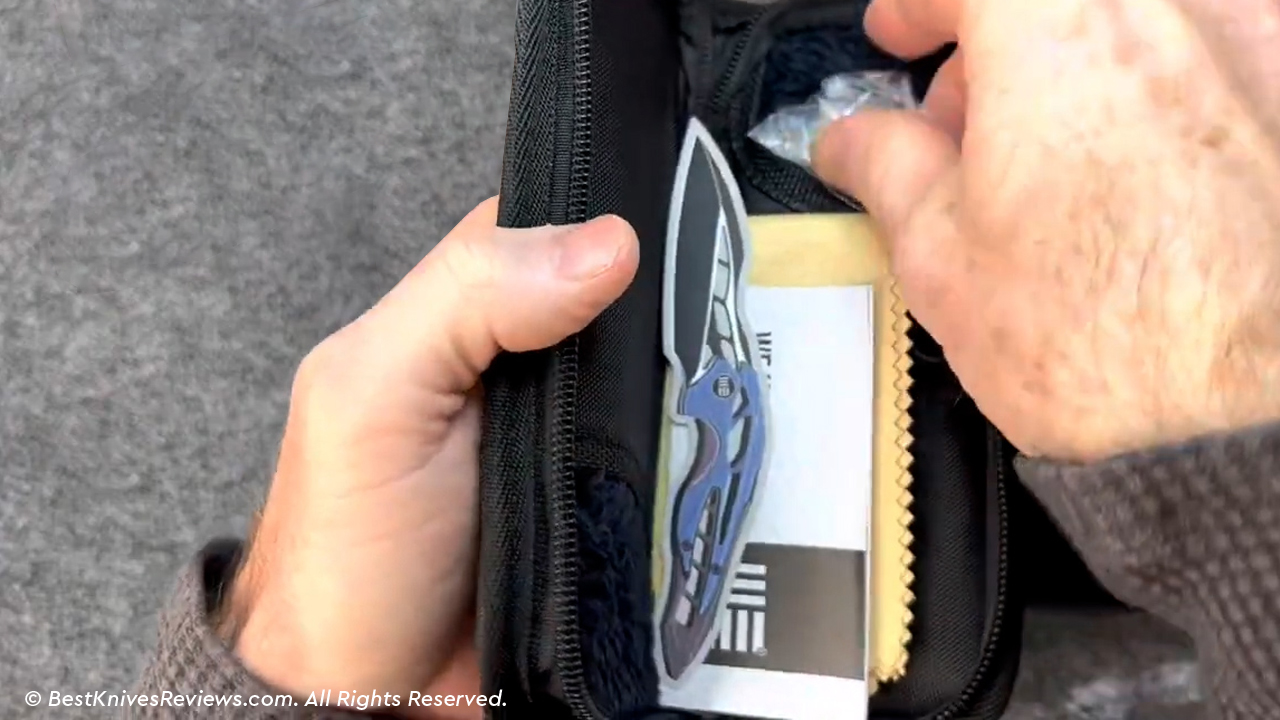

The knife came in a black nylon pouch, strapped on one side. The pouch is multipurpose and can be used to store other items. It is lined with felt inside to keep the knife secure.

The pouch included a random knife sticker, a carbon fiber cleaning cloth, an authentication certificate, and a manual with detailed descriptions and specs of the knife.

The knife came out in an excellent condition out of the box. It had immaculate finishing and a razor-sharp blade right out of the box. The blade had no scratches, it was ultra-thin for fine cutting and a smooth polish.

The handle was smooth with contoured edges, yet provided a firm grip. Titanium is a good metal for the knife handle, as it is firm yet solid. The blade is thin enough for precise cutting, with enough length and edge retention to perform various EDC tasks. The finger choil, the stop, and the spine of the blade allow the user to choke up the knife however they want. CPM 20CV is etched on to the back of the blade, signifying the blade material.

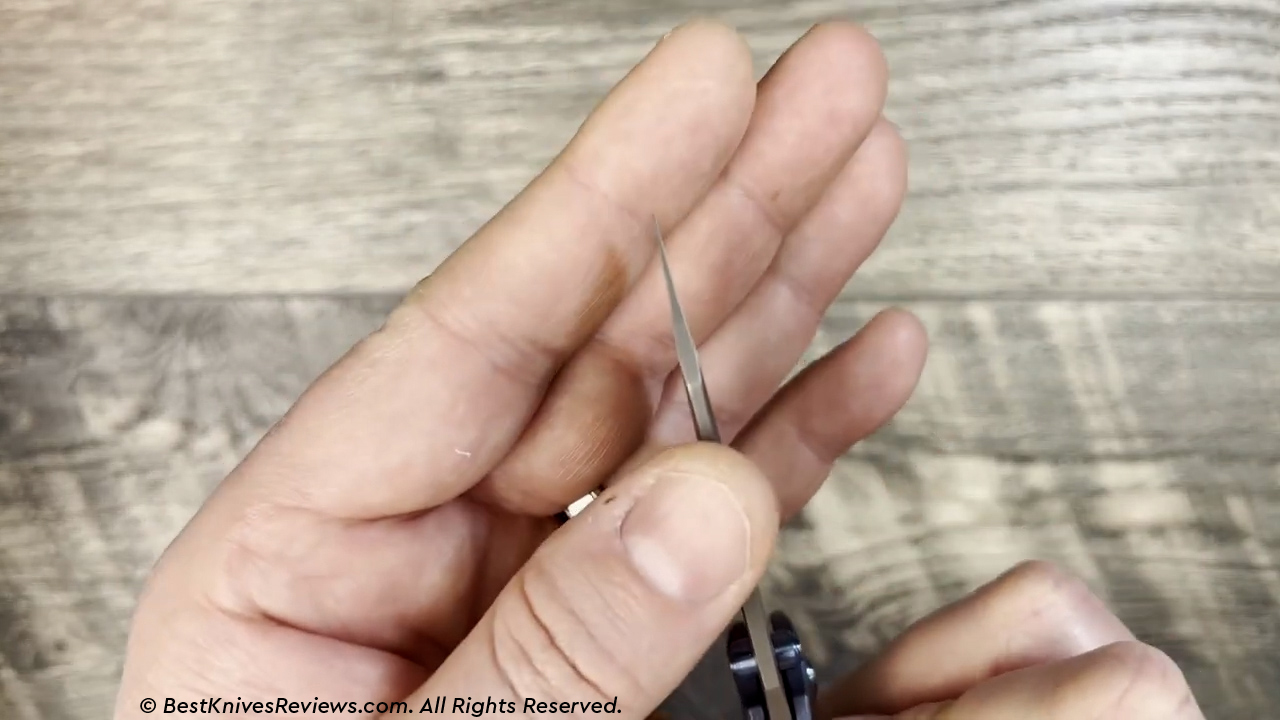

The thumb studs are in easy access – the front stud for the thumb, and the reverse one for the forefinger and middle finger action. The reverse tanto feels like a good blade design, as it fits well in the hand. The hollow grind lines are visible upon closer look. Although it is easier to sharpen, but careful consideration of the fine lines is required.

The caged ceramic ball bearings pivot and the detent make it exceptionally smooth for the blade to slide in and out.

The Blade of WE Knife High Fin Knife

The blade of WE Knife High-Fin features an ultra-premium CPM 20CV blade with a width of 1.22” and thickness of 0.13”, dimensions that are perfect for an EDC blade. It is a power metallurgy tool steel with impressive wear and corrosion, along with edge retention due to the high levels of chromium.

The reverse tanto blade shape with a harpoon tip matches the aggressive lines on the handle. It has a full-forward guard less choil that allows the user to choke up for making precise cuts. The thumb studs set right above the pivot, and are accessible for the opening and closing of the knife.

The size of the blade may look small, but is actually perfect for EDC-purposed tasks. It has enough belly to undertake kitchen-related tasks and the ripping of paper and cardboard.

The blade lacks jimping, but does have a stopper at its spine that acts as a finger guard. However, the thumb would ideally stop at the slight curve that curves up top right above the pivot.

The blade has a stonewash finish that protects it from wear, tear and scratches. It is the best finish any blade can have, and does not easily tarnish if maintained correctly. The blade also has bends, but is relatively easy to sharpen, given the sharpening choil and the hollow grind.

The Handle of We Knives High-Fin folder

The handle of High-Fin features a 4” blue titanium body that is 0.48” thick with caged ceramic ball bearings pivot and a frame lock inserted inside the body.

The handle is very smooth and contoured, with bends to grip the knife easily. A 4” handle fits perfectly well in an average-sized hand and provides ample grip. The triangulated back of the handle provides the extra space, even though it lacks a lanyard hole. The caged ceramic ball bearings make it easy to slide the blade in and out of the handle with exceptional ease.

The pocket clip is quite wide for tip-up carry, feels lightweight, and carries well and discreet in the pocket. It does not create any hot spots with the fabric.

The knife is held together by two body screws – one at the back and one on the frame lock liner. There are two screws on the pocket clip and one large pivot screw, which makes five screws in total. Since every screw has a purpose, it is easy to disassemble and reassemble it with a Torx screwdriver.

The body of the handle is finely shaped and aligns well in weight and length with the blade.

The Deployment & Lockup of WE Knife High-Fin

The High-Fin knife features thumb studs on either sides of the blade for deployment, and a frame lock situated inside the handle as its locking mechanism. Thumb studs are very easy to use, with easy access to open the knife, since the user just has to apply a light pressure on it. It opens up the blade in a snap. Pressing on the button disengages the blade lock and releasing it opens up the lock. Same goes for the reverse stud that you can access with the middle finger. It operates very smoothly.

Access to the lock bar is easy because of the chamfering and a little bit of cutout. It allows opening and closing the knife in multiple ways – with thumb, forefinger, or the back of the middle finger.

The frame lock works just as fine. It is like the R.I.L lock, but stronger and simpler. The frame is thicker and covers almost the entire handle. The cutout along the axis of the spine has a relief cut that creates inward pressure. The lock bar springs inward when the blade is opened that engages the rear of the blade tang to lock the blade in place.

The detent ball and the caged ceramic ball bearings make the lockup and open-up extremely smooth, no matter how frequently you open and close the knife. The detent ball engages with the hole in the base of the blade to keep it closed, and provides tension for snappy opening. The stop pin controls the blade’s position and helps eliminate wear on the lock bar.

Field Test of WE Knife High-Fin

We tested the High-Fin the field by shredding off a piece of wooden plank, and it turned out to be a rather easy task. It did not require much force, we were able to shred it easily, thanks to the incredibly sharp blade. It allows choking up the blade and provides a firm grip.

The pocket clip slides and hangs easily in the pocket, without creating any hot spots, and takes up little space. It also feels lightweight, as it weighs only 3.49 ounces.

We also cut paper and cardboard with ease. The reverse tanto proved to be beneficial and not easily chipped. The CPM 20CV showed its high quality and acted tough.

Pro’s & Con’s of WE Knife High Fin

PRO’s

Con’s

Comparisons

WE Knife High-Fin vs RekkeR

WE Knife High-Fin and RekkeR fall on the same spectrum when it comes to knife features. Both the knives feature CPM 20CV blade and a titanium handle. They also weigh almost the same, with only slight difference in length. RekkeR is only slightly longer than High-Fin.

Both have stonewash finish and a tip-up carry pocket clip. Both the knives also have a frame lock with caged ceramic ball bearings pivot. Where RekkeR is a flipper, High-Fin has thumb studs. Both the deployment mechanisms work really well, and allow frequent opening and closing of the knife.

However, RekkeR is a bit more expensive than High-Fin. Both the knives also have almost the same blade stock thickness. Both the knives come with black nylon pouch for safe keeping.

Both the knives also work well when it comes to functionality and performance. When it comes down to these two knives, it depends what you want to use them for. Both are EDC knives with slight differences.

We Knife Co Ltd RekkeR Prices |

||

|---|---|---|

|

|

Check Price at Blade HQ |

|

Check Price at Chicago Knife Works | |

Conclusion

We found WE Knife High-Fin to a knife worth its features, functions and performance. It features ultra-premium CPM 20CV blade and a titanium handle. It has thumb studs as its deployment and frame lock as its locking mechanism. It costs more than other knives with similar features, but also performs well.

The size of High-Fin is just ample enough to fit in an average-sized hand and is lightweight. The deployment and lockup is very smooth, owing to the detent that is just light enough and the caged ceramic ball bearings pivot.

Mentions & Reviews by others

We have written a detailed review about WE Knife High Fin

GearJunkkie has also reviewed the same product.

If you know someone else have written a review about this item, do let us know.